DTF printing is changing the way companies print apparel—no question about it. The color pops, the prints last, and you can use it on a wide range of fabrics. However, here’s the catch that often gets overlooked: Hot Peel vs. Cold Peel DTF. Should you opt for a hot peel or a cold peel for your transfers? It may seem minor, but that choice can significantly impact your production speed, the final product’s appearance, and your overall costs.

This guide explains the difference between hot and cold peel DTF, weighs pros and cons, and helps you choose the best peel method for DTF based on your workflow.

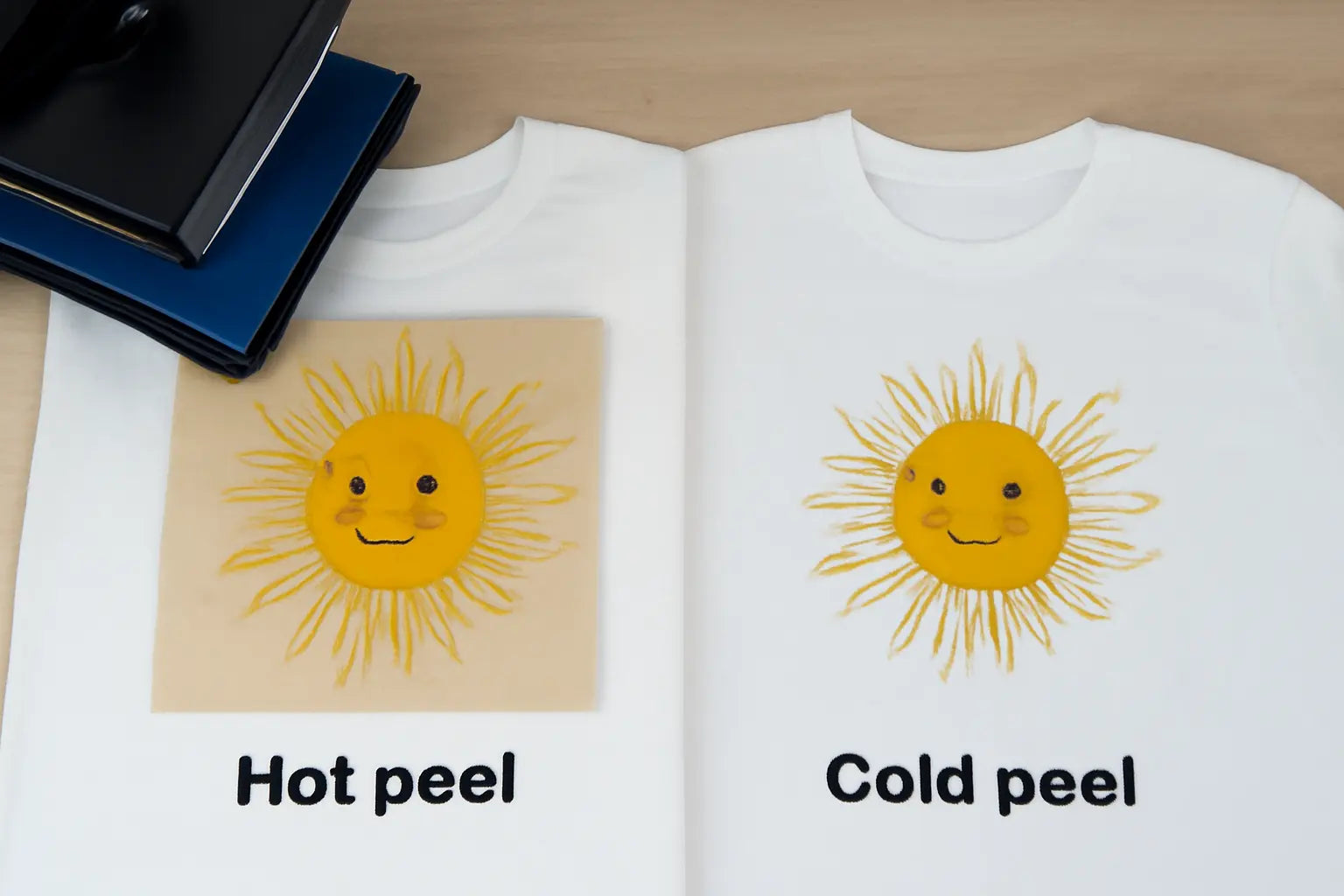

Hot Peel vs. Cold Peel DTF Transfers: The Core Difference

The core difference between the two is the time of peeling. It’s all about when you rip the film off after pressing.

-

Hot peel? Yank it off right away, while it’s still sizzling.

- Cold peel? You let it cool down before peeling.

It doesn’t sound like a big deal, but when it comes to print quality, it changes everything: the look, the feel, and the durability of the print.

What Exactly is the Hot Peel?

Basically, with DTF printing hot peel, you don’t have to wait around. As soon as you lift the heat press, you can peel the PET film off; you're done. These are designed to let you get started quickly, so you can produce shirts and other accessories speedily and sell faster.

Advantages of Hot Peel DTF

Here’s why hot peel might be the right solution for you:

-

It’s quick and is perfect for mass production. No cooling-off period.

-

Saves serious time. If you’re in a hurry, hot peel’s your best friend.

- Feels nice, too—usually leaves the print a bit softer.

DTF hot peel instructions tip: Use firm pressure, high heat (around 320°F), and peel immediately after pressing.

Disadvantages of Hot Peel DTF

Here’s why it may not be so great for your project:

-

Timing’s tricky. Peel too soon or too late? You might just mess up your print.

- You gotta have your heat press game on point. If your temperature or pressure is incorrect, you may experience a loss of print quality.

For accurate results, always follow the manufacturer’s DTF hot peel guide and run tests to perfect your workflow.

When to Use Cold Peel DTF?

Cold peel DTF transfers—basically, you need to let the PET film cool off before peeling it away. No shortcuts here. The design requires a minute (or two) to adhere tightly to the fabric.

Advantages of Cold Peel DTF

-

Sticks like glue. The bond is rock-solid, especially when working with thick or bumpy fabrics.

-

The finish is sharp. Think crisp, durable prints that don’t flake off after two washes.

- Not as fussy. If your press game isn’t 100% perfect, cold peel is a little more forgiving.

The cold peel DTF temperature is typically 300°F–315°F, followed by a DTF cold peel time of 30–60 seconds before the peel is applied.

Disadvantages of Cold Peel DTF

Here are a few disadvantages of cold peel DTF:

-

No instant gratification—if you’re in a rush, a cold peel might test your patience.

- Sometimes it’s a bit too shiny. That glossy look isn’t for everyone. If you’re after a super-matte finish, hot peel might be a better option.

Best Peel Method for DTF

So, which peel is the best? Honestly, it’s not a one-size-fits-all thing. It depends on your production needs, the types of fabric, and your clients' expectations.

Grab a hot peel if:

-

You’re all about speed. Blink and it’s done.

-

Your fabrics are cotton or poly blends.

- You don’t need absolute perfection, just want to keep things moving.

Go for a cold peel if:

-

Your fabrics are thick and textured, requiring strong adhesion.

-

You want your prints to survive for years to come.

- You want rich details, color, and extreme accuracy.

So, what's the best peel for vibrant DTF results? If sharp color and detail are your priority, cold peel is the solution. But for bulk runs and time savings, hot peel wins.

Key Variables to Consider

Beyond peel style, your outcome also depends on:

-

Heat and pressure: A few degrees or PSI off can ruin adhesion.

-

Fabric compatibility: Know which materials are good with hot or cold peel.

-

Ink and powder quality: Don’t skimp.

- Peel technique: It’s a finesse game. Go slow and steady for clean results.

Why Choose Music City DTF?

Music City DTF is obsessed with quality. Inks, powder, PET film—everything here is from the top shelf. We offer fast turnarounds, custom options (including hot or cold peel), are made in the USA, and have a customer support team that actually answers emails. With rigorous testing for peel reliability, color accuracy, and durability, Music City DTF is the go-to for professionals who want it done right, the first time.

Final Thoughts

The entire debate surrounding hot peel vs. cold peel DTF transfers comes down to timing, finish, and workflow. Hot peel gives you speed and a soft finish—perfect for fast-paced shops and bulk orders. Cold peel offers durability and detail, ideal for high-end or complex jobs. If you’re serious about quality, performance, and long-term consistency, work with a provider that delivers both options, tested to perfection.

Ready to try peels for your fabrics? Check out our DTF Sample Pack to start testing. Whether you’re experimenting with DTF cold peel time or comparing the advantages of hot peel DTF vs. the advantages of cold peel DTF, we’ve got the products and support to help you get started.